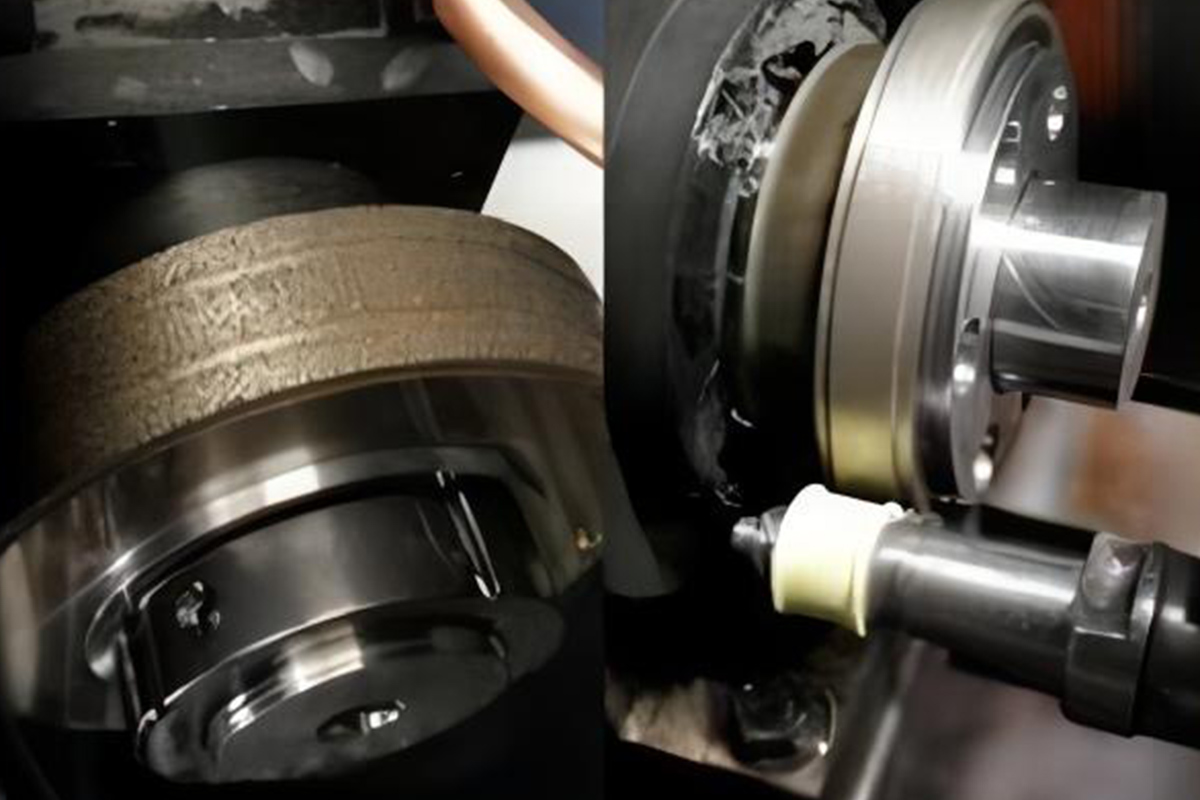

Apa masalah sing bakal ditemoni ing proses penggilingan roda gilingan ganda?Piyé carané kudu ditindakké?

1. CBN grinding wheel Burns workpiece sak mecah

(1).Atose CBN grinding wheel dhuwur banget: ngganti mecah wheel karo atose cocok.

(2).Arah nozzle coolant ora bener utawa aliran ora cukup: nyetel arah nozzle coolant kanthi bener lan aliran tambah.

(3).Klamben CBN grinding wheel ora nyukupi: ganti CBN grinding wheel dresser lan nindakake grinding wheel dressing maneh.

(4).Tingkat feed grinding workpiece gedhe banget: nyuda feed rate kanthi bener.

(5).Coolant ora disaring resik: mriksa lan nyetel sistem cooling maneh.

2.Discontinuity ukuran workpiece mecah relatif miskin

Kekerasan rodha nggiling sing dipilih gedhe banget: ngganti roda nggiling kanthi kekerasan sing cocog.

3.Garis geter katon ing lumahing CBN mecah wheel

(1).Tingkat feed gedhe banget: nyuda tingkat feed.

(2).Roda mecah hard: nyuda atose, nambah kacepetan rotasi workpiece, lan nyepetake klamben.

(3).Roda nggiling ora diratakake: roda nggiling dipotong maneh lan getaran alat mesin dicenthang.

4. Kontinuitas ukuran workpiece umum kurang

Kekerasan saka setir mecah sing dipilih kurang banget: ngganti setir mecah kanthi kekerasan sing cocog.Long-urip resin CBN mecah wheel kanggo mecah pungkasan

5. The roughness lumahing workpiece sawise mecah punika relatif miskin

(1).Kacepetan workpiece banget alon: akselerasi kacepetan workpiece.

(2).Coolant ora disaring kanthi cukup: priksa manawa sistem panyaring kanggo nyetel coolant normal.

(3).Tingkat feed sing berlebihan: alon-alon tingkat feed.

(4).Kacepetan rotasi nggiling wheel kurang banget: nyetel kacepetan rotasi mecah wheel.

(5).Klamben ora nyukupi saka grinding wheel: nyetel utawa ngganti CBN grinding wheel dresser kanggo klamben.

(6).Ukuran wheel grinding sing dipilih ora cocog: ngganti ukuran wheel grinding sing cocog.

Wektu kirim: Feb-23-2023