Keramik Capillary Bonding Capillary Kanggo kemasan semikonduktor

Aplikasi produk

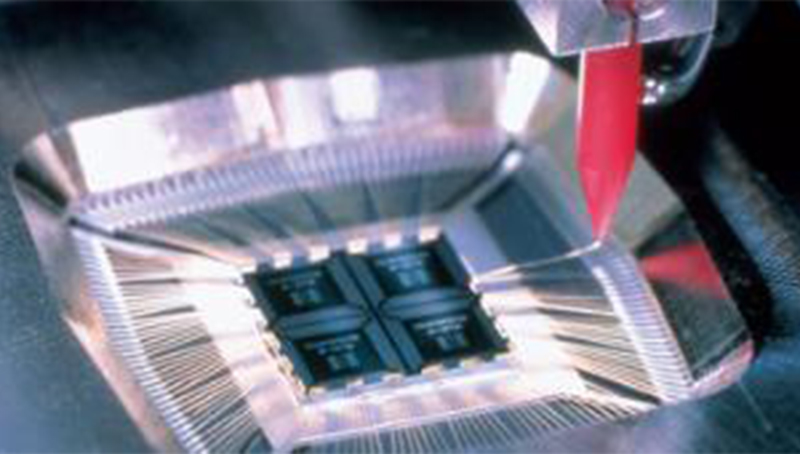

Capillary Keramik minangka alat keramik axisymmetric kanthi bolongan ing arah vertikal, sing kalebu komponen keramik struktur mikro sing akurat.Ing babagan aplikasi, Capillary Keramik digunakake minangka alat ikatan kawat ing proses ikatan kawat.WireBonding bisa nggawe timbal logam rapet las karo pad landasan kanthi nggunakake kabel logam tipis (tembaga, emas, lan sapiturute) lan panas, meksa, lan energi ultrasonik, supaya minangka kanggo éling interconnection electrical antarane Kripik lan landasan lan exchange informasi antarane. kripik.Cocog kanggo ikatan lan kemasan SCR, SAW, LED, diode, triode, chip IC lan sirkuit liyane.

kaluwihan produk

OPT Cutting Tools Co., LTD.dumunung ing Shenzhen, Guangdong, China.Iki minangka perusahaan sing nggabungake produksi, penjualan, riset lan pangembangan.Lan bisa nindakake desain lan nggawe gambar, bahan lan alat non-standar.Teguh nganggo bahan produksi baris pertama domestik kanggo njamin stabilitas macem-macem bahan.Ngontrol proses produksi kanthi ketat kanggo njamin kualitas alat.Perusahaan kasebut nduweni kekuwatan teknis sing akeh, kapasitas produksi sing kuwat, manajemen ilmiah, kanthi tujuan "slamet kanthi kualitas, pangembangan kanthi reputasi", lan terus maju kanggo nyedhiyakake produk sing luwih apik kanggo para pelanggan.

Pangiriman sing akurat, layanan apik

1. OPT Cutting Tools duwe sistem produksi, manufaktur lan transportasi sing lengkap.Ing wektu pangiriman.

2. Komunikasi lan ijol-ijolan siji-siji bisa ditindakake karo para pelanggan supaya bisa menehi alat ikatan Keramik sing luwih cocog lan luwih apik.

3. Ngatur paramèter khusus miturut syarat khusus pelanggan;

Nganyarke Material Capillary Bonding

Ing basis saka aluminium oksida asli, zirconia, kromium oksida, lan sapiturute ditambahake kanggo nggawe struktur molekul saka Keramik Kapiler luwih kompak, karo atose luwih, resistance nyandhang luwih lan urip layanan maneh.Ngurangi nyandhang lan wektu panggantos tip cleaver keramik nalika welding kabel.

Dhuwur tliti, dhuwur dimensi tliti, kurang mesin lan permukaan Gamelan.

Produk kasebut nduweni presisi dhuwur, presisi dimensi sing dhuwur, jumlah mesin sing kurang lan permukaan sing lancar.

Struktur Capillary Keramik banget pas lan Komplek, lan dimensi tombol duwe impact gedhe ing efek iketan kabel.OPT Cutting Tools ngontrol proses produksi kanthi ketat kanggo njamin kualitas alat.Kanggo entuk akurasi produk sing dhuwur, akurasi dimensi sing dhuwur, mesin sing kurang, lan permukaan sing lancar.Perusahaan kita setya ing R&D lan produksi alat ikatan keramik domestik medium lan dhuwur ing bidang kemasan IC.Wêdakakêna keramik lan bagean embrio rampung dikembangake lan diprodhuksi kanthi mandiri.

![]()

BPP: 150μm(μm/mil)

| Bagian NO. | WD | H | T | CD | OR | α | Θ | CA |

| A-1 | 38/1.5 | 51/2.0 | 229/9.0 | 102/4.0 | 38/1.5 | 8° | 30° | 120° |

| A-2 | 38/1.5 | 51/2.0 | 152/6.0 | 66/2.6 | 10/0.4 | 0° | 30° | 90° |

| A-3 | 38/1.5 | 51/2.0 | 229/9.0 | 86/3.4 | 102/4.0 | 0° | 30° | 90° |

| A-4 | 38/1.5 | 51/2.0 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90′ |

| A-5 | 38/1.5 | 56/2.2 | 239/9.4 | 102/4.0 | 38/1.5 | 8° | 30° | 120° |

| A-6 | 38/1.5 | 56/2.2 | 229/9.0 | 96/3.8 | 102/4.0 | 0° | 30° | 90° |

| A-7 | 38/1.5 | 56/2.2 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90° |

| A-8 | 38/1.5 | 64/2.5 | 239/9.4 | 102/4.0 | 38/1.5 | 6° | 30° | 120° |

| A-9 | 38/1.5 | 64/2.5 | 203/8.0 | 89/3.5 | 61/2.4 | 0° | 30° | 90° |

| A-10 | 51/2.0 | 64/2.5 | 191/7.5 | 81/3.2 | B/0.3 | 0° | 30° | 90° |

| A-11 | 51/2.0 | 64/2.5 | 292/11.5 | 102/4.0 | 127/5.0 | 0° | 30° | 90° |

| A-12 | 51/2.0 | 76/3.0 | 356/14.0 | 122/4.8 | 152/6.0 | 0° | 30° | 90° |

| A-13 | 51/2.0 | 89/3.5 | 419/16.5 | 135/5.3 | 178/7.0 | 0° | 30° | 90° |

| A-14 | 51.64/2.0.2.5 | 76/3.0 | 330/13.0 | 140/5.5 | 64/2.5 | 8° | 30° | 120° |

| A-15 | 64.76/2.5.3.0 | 89/3.5 | 330/13.0 | 127/5.0 | 64/2.5 | 8° | 30° | 120° |

| A-16 | 64.76/2.5.3.0 | 102/4.0 | 330/13.0 | 140/5.5 | 64/2.5 | 8° | 30° | 120° |

| A-17 | 76/3.0 | 102/4.0 | 483/19.0 | 168/6.6 | 203/8.0 | 0° | 30° | 90° |

BPP: 140μm(μm/mil)

| Bagian NO. | WD | H | T | CD | OR | α | Θ | CA |

| B-1 | 22/0.9 | 33/1.3 | 140/5.5 | 64/2.5 | 20/0.8 | 8° | 30° | 120° |

| B-2 | 25/1.0 | 38/1.5 | 165/6.5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-3 | 25/1.0 | 38/1.5 | 89/3.5 | 53/2.1 | B/0.3 | 0° | 30° | 90° |

| B-4 | 25/1.0 | 38/1.5 | 114/4.5 | 53/2.1 | 8/0.3 | 0° | 30° | 90° |

| B-5 | 25/1.0 | 38/1.5 | 178/7.0 | 64/2.5 | 76/3.0 | 0° | 30° | 90° |

| B-6 | 25/1.0 | 38/1.5 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-7 | 25/1.0 | 43/1.7 | 165/6.5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-8 | 25/1.0 | 43/1.7 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-9 | 25.30 / 1.0.1.2 | 43/1.7 | 229/9.0 | 74/2.9 | 30/1.2 | 8° | 30° | 120° |

| B-10 | 25.30 / 1.0.1.2 | 43/1.7 | 152/6.0 | 59/2.3 | B/0.3 | 8° | 30° | 120° |

| B-11 | 25.30 / 1.0.1.2 | 43/1.7 | 203/8.0 | 74/2.9 | 89/3.5 | 0° | 30° | 90° |

| B-12 | 25.30 / 1.0.1.2 | 46/1.8 | 229/9.0 | 74/2.9 | 38/1.5 | 8° | 30° | 120° |

| B-13 | 30/1.2 | 46/1.8 | 203/8.0 | 76/3.0 | 89/3.5 | 0° | 30° | 90° |

BPP: 100μm(μm/mil)

| Bagian NO. | WD | H | T | CD | OR | α | Θ | CA |

| C-1 | 25/1.0 | 38/1.5 | 130/5.1 | 53/2.1 | 30/1.2 | 11 | 30° | 90° |

| C-2 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 11 | 30° | 90° |

| C-3 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 8' | 30° | 90° |

| C-4 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 4' | 30° | 90° |

| C-5 | 30/1.2 | 41/1.6 | 130/5.1 | 59/2.3 | 30/1.2 | 11 | 30° | 90° |

BPP: 90μm(μm/mil)

| Bagian NO. | WD | H | T | CD | OR | α | Θ | CA |

| D-1 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 11° | 30° | 90° |

| D-2 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 8° | 30° | 90° |

| D-3 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 4° | 30° | 90° |

| D-4 | 25/1.0 | 35/1.4 | 109/4.3 | 51/2.0 | 20/0.8 | 11° | 30° | 90° |

| D-5 | 30/1.2 | 38/1.5 | 109/4.3 | 51/2.0 | 20/0.8 | 11° | 30° | 90° |

| D-6 | 30/1.2 | 38/1.5 | 109/4.3 | 53/2.1 | 1310.5 | 8° | 30° | 90° |

| D-7 | 30/1.2 | 38/1.5 | 109/4.3 | 53/2.1 | 13/0.5 | 4° | 30° | 90° |

BPP: 80μm(μm/mil)

| Bagian NO. | WD | H | T | CD | OR | α | Θ | CA |

| E-1 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0.5 | 4° | 30° | 90° |

| E-2 | 25/1.0 | 33/1.3 | 99/3.9 | 4B/1.9 | 13/0.5 | 8° | 30° | 90° |

| E-3 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0.5 | 11° | 30° | 90° |

| E-4 | 25/1.0 | 35/1.4 | 99/3.9 | 46/1.8 | 13/0.5 | 11° | 30° | 90° |

| E-5 | 30/1.2 | 38/1.5 | 99/3.9 | 51/2.0 | 13/0.5 | 4° | 30° | 90° |

| E-6 | 30/1.2 | 3B/1.5 | 99/3.9 | 51/2.0 | 13/0.5 | 8° | 30° | 90° |

BPP: 70μm(μm/mil)

| Bagian NO. | WD | H | T | CD | OR | α | Φ | CA |

| F-1 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1.7 | 10/0.4 | 8° | 30° | 90° |

| F-2 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1.7 | 10/0.4 | 4° | 30′ | 90° |

| F-3 | 25/1.0 | 33/1.3 | 91/3.6 | 43/1.7 | 13/0.5 | 11° | 30′ | 90° |

BPP: 60μm(μm/mil)

| Bagian NO. | WD | H | T | CD | OR | α | Φ | CA |

| G-1 | 23/0.9 | 28/1.1 | 81/3.2 | 35/1.4 | 13/0.5 | 11° | 30° | 90° |

| G-2 | 25/1.0 | 30/1.2 | 81/3.2 | 35/1.4 | 13/0.5 | 11° | 30° | 90° |